HEAT PUMP

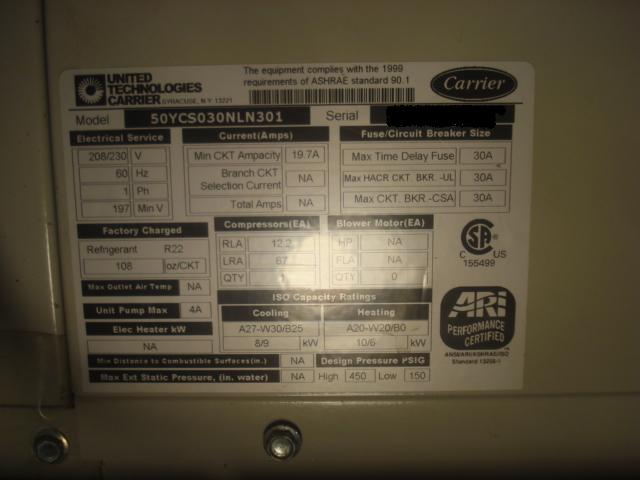

We chose Carrier owned by United Technologies Company.

General Operation of a Heat Pump from Encyclopedia:

http://en.wikipedia.org/wiki/Heat_pump

Heat pump info links:

http://www.residential.carrier.com/products/acheatpumps/geoheatpumps.shtml

http://www.acfactoryoutlet.com/home.asp?id=141&dif=no

http://www.grainger.com/Grainger/wwg/productIndex.shtml

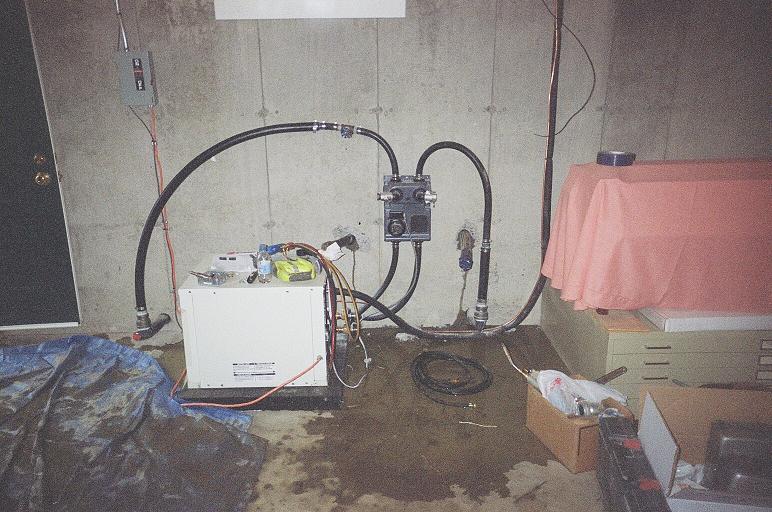

Here is the white Carrier $2600 Heat Pump in the basement with the $665 flow controller circulating pump Carl LePere mounted to the wall.

The main thing you want is a high COP = Coefficient of Performance.

This model has a COP of 4.7 which means that 1 watt of electricity into this system produces the same BTU heat as 4.7 watts into a direct heat conversion unit.

My well water runs through a filter canister here, not through the Potassium Chloride System.

We added about 7 gallons of town water with some chlorine to prevent bacteria growth in the closed loop.

See what we learn from computer cooling experts: http://www.procooling.com/index.php?func=articles&disp=36&pg=2

Water right from the well might form calcite deposits inside the pipe and wreck the friction and heat transfer.

The reason propylene glycol is limited to 20% is that it gets like a slurry at cold temps and does not pump well.

Indoors at higher concentrations at 50% its ok.

Propylene Glycol antifreeze is selected because it is a completely biodegradable food based antifreeze.

Not that the 160 psi pipe operating at 40 psi should ever rupture, but we want to avoid a fuel oil tank seepage disaster to the soil.

Hooked up Friday night. The lower loops are the inlet and outlet. The higher level black conduits thru the wall are the 100' reserve.

Carl has a shutoff sensor out about 25', and I have 5 temperature recording thermometers out at 5' from the concrete wall in the soil.

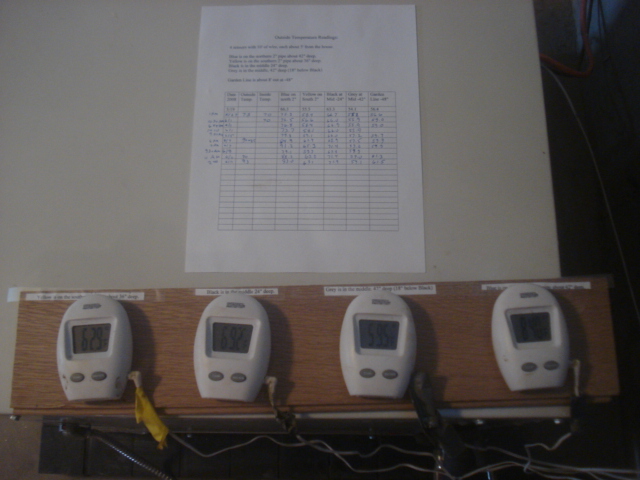

The Working Carrier Heat Pump with 4 thermometers to record soil temperatures

During the heat wave of early June, with outside temps in the 90's, yellow intake line was in the 60's.

Blue outlet line was in the 90 degree range.

So we were cooling our house by putting about 25 degrees of heat into one end going outside.

And by the time that heated water returned in the yellow thermometer line, it was chilled by the ground to 60 degrees again.

Mid point soil readings were in the high 50's.

The 4' deep probe was cooler than 2' deep probe that was being warmed by the solar heat from above.

Outside Temperature Readings:

| 5 sensors with 10' of wire, each about 5' from the house. |

|

Blue is on the northern 2" pipe about 42" deep. Yellow is on the southern 2" pipe about 36" deep. Black is in the middle 24" deep. Grey is in the middle, 42" deep (18" below Black) Garden Line is about 8' out at -48" |

|

Time |

Date 2008 |

Outside Temp. |

Blue on north 2" Outlet pipe |

Yellow on South 2"

Inlet pipe |

Basement Temp. |

Grey at Mid -42" |

Garden Line -48"

|

|

|

5/19 |

|

66.3 |

55.5 |

63.3 |

54.1 |

56.4 |

|

1:00 pm |

5/27 |

73 |

75.3 |

58.4 |

66.7 |

55.2 |

56.6 |

|

10:30am |

6/1 |

|

72.5 |

56.6 |

66.0 |

55.9 |

59.0 |

|

6:45 pm |

6/1 |

|

76.8 |

58.4 |

66.9 |

55.9 |

59.0 |

|

10:00pm |

6/1 |

|

73.7 |

58.1 |

66.0 |

55.9 |

- |

|

9:30 am |

6/5 |

74.3 |

59.1 |

66.0 |

57.2 |

59.7 |

|

|

6:00 pm |

6/7 |

87 |

84.9 |

62.4 |

68.9 |

57.5 |

59.9 |

|

7:00 pm |

6/7 |

|

91.2 |

65.3 |

71.4 |

57.2 |

59.9 |

|

9:30 am |

6/8 |

|

79.1 |

59.7 |

67.8 |

57.9 |

|

|

11:00 am |

6/11 |

90 |

88.3 |

63.8 |

71.4 |

59.0 |

61.3 |

|

2:40 pm |

6/11 |

93 |

93.0 |

65.1 |

71.9 |

59.1 |

61.5 |

|

9:45 pm |

6/11 |

|

84.7 |

63.3 |

70.1 |

60.9 |

|

|

8:00 pm |

6/13 |

80 |

96.6 |

70.1 |

73.9 |

60.9 |

|

| 9:15 pm | 6/13 | 80 | 94.4 | 68.9 | 74.3 | 61.3 | |

| 8:00 am | 6/14 | 84.3 | 64.5 | 68.9 | 61.3 | 64.5 | |

| 3:30 pm | 6/18 | 70 | 84.9 | 63.1 | 68.5 | 62.9 | |

| 1:10 pm | 6/23 | 70 | 88.3 | 63.3 | 70.5 | 63.1 | |

| 12:30 pm | 7/1 | 75 | 94.8 | 68.0 | 71.6 | 63.6 | |

| 3:30 pm | 7/7 | 80 | 94.8 | 68.0 | 71.9 | 65.3 | 68.7 |

| 10:00 pm | 8/1 | 80 | 93.0 | 76.8 | 75.9 | 69.2 | 72.6 |

| 8:00 am | 8/2 | 75 | 84 | 71.4 | 71.4 | 69.6 | |

|

9:00 am |

8/13 |

70 |

79.7 |

68.7 |

69.9 |

67.8 |

71.4 |

| 9:00 am | 8/25 | no ac all week | 63.6 | 68.3 | 70.7 | 68.3 | |

| Blue | Yellow | Black | Grey | Garden | |||

|

Heat mode |

9/21 |

|

50.3 |

65.4 |

68.5 |

64.9 |

68.5 |

|

|

10/29 |

|

35.7 |

55.4 |

63.1 |

53.0 |

|

|

|

11/9 |

|

33.2 |

54.8 |

63.5 |

50.9 |

57.3 |

|

|

11/11 |

40 |

31.9 |

53.7 |

61.8 |

50.7 |

|

|

|

11/12 |

29 |

30.6 |

52.1 |

62.7 |

50.9 |

|

|

|

11/14 |

40 |

31.5 |

52.5 |

62.7 |

49.8 |

55.7 |

|

8:00 am |

11/15 |

55 |

31.9 |

52.8 |

62.9 |

49.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note that during the heat wave of early June, the heat pump was averaging a transfer of 25 degrees

= 65 from the yellow inlet pipe to 90 degrees for the blue outlet pipe.

That's 25 degrees worth of heat being pumped back into the ground.

And when the geo water returns it is cooled back to 65 degrees. Just as expected!

On Nov 12, in freezing outside temperature of 29, 52.1 incoming -30.6 pumped out = 21.5 degrees used.

|

Time |

Date 2008 |

Outside Temp. |

Blue on north 2" Outlet pipe |

Yellow on South 2"

Inlet pipe |

Black at Mid -24" |

Grey at Mid -42" |

Garden Line -48" & pressures |

| 11/16 | 43 | 29.7 | 52.8 | 62.9 | 49.1 | ||

| 7 am | 11/18 | 25 | 29.3 | 51.0 | 63.1 | 48.7 | |

| 8 am | 11/18 | 30 | 27.7 | 50.9 | 62.9 | 49.1 | |

| noon | 11/18 | 35 | 30.2 | 51.8 | 62.4 | 49.1 | |

| 7 am | 11/19 | 19 | 27.9 | 49.4 | 62.9 | 49.1 | |

| 8:30 am | 11/19 | 25.4 | 48.3 | ||||

| 9:15 am | 11/19 | 27.2 | 48.7 | 64.5 | 48.3 | ||

| 7:30 am | 11/20 | 24.8 | 48.3 | ||||

| 7 am | 11/21 | 20 | 24.8 | 47.3 | 62.0 | 48.0 | 53.0 |

| 10 am | 11/22 | 20 | 24.8 | 46.2 | 61.1 | 47.3 | |

| 8:20 am | 11/23 | 15 | 24.8 | 46.0 | 61.1 | 46.9 | |

| 9 ;30 am | 11/24 | 25 | 25.4 | 46.9 | 58.2 | 46.0 | |

| 7 am | 11/25 | rain | 25.6 | 47.3 | 59.9 | 45.3 | |

| 9 am | 11/25 | 38 | 26.5 | 47.6 | 59.9 | 45.3 | 50.5 |

| noon | 11/26 | 40 | 26.3 | 46.2 | 59.3 | 44.7 | |

| 3 pm | 11/28 | 28.1 | 48.0 | 56.3 | 44.2 | ||

| 11 am | 11/29 | 40 | 24.8 | 44.7 | 63.6 | 43.8 | |

| noon | 12/1 | 40 | 26.6 | 46.9 | 58.1 | 43.8 | 48.0 |

| noon | 12/2 | 40 | 26.5 | 46.9 | 59.3 | 43.3 | |

| 9:30 am | 12/3 | 36 | 24.8 | 45.1 | 60.6 | 42.9 | |

| 7:30 am | 12/4 | 30 | 24.8 | 45.6 | 59.9 | 42.9 | |

| 330pm | 12/5 | 35 | 24.8 | 46.5 | 59.3 | 42.6 | |

| 8am | 12/6 | 20 | 24.8 | 46.0 | 57.7 | 42.6 | |

| 9am reset | 12/6 | 23.0 | 45.1 | 58.4 | 42.9 | ||

| 1030am | 12/7 | 25 | 23.0 | 44.4 | 60.2 | 42.4 | |

| 6pm | 12/7 | 25 | 24.8 | 45.6 | 58.4 | 42.6 | |

| 8am reset | 12/8 | 10 | 21.2 | 44.4 | 59.0 | 42.0 | |

| 2pm Carl | 12/8 | 23.0 | 45.6 | 58.1 | 42.0 | 15 min timer | |

| 12/10 | 24.8 | 43.3 | 57.9 | 41.5 | |||

| 330pm | 23.0 | 43.5 | 59.3 | 40.8 | |||

| 9 am | 12/16 | 24.8 | 44.4 | 59.5 | 39.9 | 45.3 | |

| 630am | 12/19 | 21.4 | 43.3 | 59.0 | 39.7 | ||

|

5am snow |

12/21 |

|

21.2 |

42.9 |

58.2 |

39.7 |

|

| 1pm | 12/23 | 23.0 | 43.3 | 58.1 | 39.3 | ||

| 6am | 12/24 | 21.6 | 42.6 | 58.4 | 38.8 | 45.1 | |

| 2pm | 12/26 | 19.4 | 42.9 | 57.3 | 38.1 | ||

| 2pm | 12/27 | 21.2 | 42.6 | 57.3 | 37.7 | ||

| 8am | 12/28 | 23.0 | 43.3 | 57.2 | 37.5 | ||

| off 9am | 1/1/09 | 5 | 23.0 | 45.1 | 55.2 | 37.7 | 44.4 |

| Tested off | for one | day (OK) | 275 gallons | $188.9per | backup | works | |

| 8am | 1/2 | 15 | 20.3 | 43.3 | 56.4 | 37.7 | |

| 9am | 1/2 | 19.8 | 42.9 | 56.6 | 37.7 | ||

| 1pm | 1/2 | 21.2 | 42.9 | 56.6 | 37.7 | 44.4 | |

| 8pm | 1/4 | 25 | 19.6 | 42.9 | 57.3 | 37.7 | |

| noon | 1/5 | 30 | 19.4 | 42.9 | 56.0 | 37.5 | |

| 5pm | 1/5 | 21.2 | 43.5 | 56.1 | 37.5 | ||

| off for | 10 days | ||||||

| 1 am | 1/16 | -5 | 21.8 | 43.5 | 50.9 | 37.0 | |

| 9 am | 1/16 | 0 | 23.0 | 43.3 | 51.2 | 36.8 | |

| 4 pm | 1/16 | 10 | 21.2 | 42.9 | 52.5 | 36.8 | |

| 4pm | 1/19 | 19.8 | 42.6 | 54.1 | 36.3 | ||

| noon | 1/22 | 15 | 21.2 | 42.0 | 54.1 | 35.8 | |

| 5pm | 1/28 | 25 | 21.2 | 42.4 | 55.2 | 35.2 | |

| 3pm | 1/30 | 25 | 21.6 | 42.4 | 54.3 | 34.8 | |

| 4pm | 1/31 | 28 | 23.0 | 41.7 | 54.3 | 34.5 | |

| heat | pump | running | only | 3 minutes | before | stopping | |

| 10 am | 2/1 | 20 | 23.0 | 41.7 | 54.6 | 34.8 | |

| half tank | oil | Carl | adds | probe | cutoff | temp | 30deg |

| and | Carl | removes | air | & adds | 12 gals | prop&water | |

| Press | rises | from | 20 psi | to 25 psi | or 30 when | running | |

| 10 pm | 2/2 | 17.6 | 40.8 | 57.5 | 34.5 | ||

| 7am | 2/3 | 16.4 | 39.0 | 57.9 | 34.5 | ||

| noon | 2/3 | 17.6 | 39.3 | 57.5 | 34.5 | 25psi 25psi | |

| 29/31 run | |||||||

| 10 pm | 2/3 | 15.8 | 38.1 | 58.1 | 34.3 | ||

| 7 am | 2/4 | 10 | 14.0 | 35.2 | 59.7 | 34.3 | |

| 10 am | 2/4 | 15.8 | 37.2 | 57.0 | 34.5 | 24 25 | |

| 1 pm | 2/4 | 17.6 | 38.3 | 55.9 | 34.3 | ||

| 7 am | 2/5 | 0 | 14.0 | 33.6 | 60.6 | 34.3 | 27/31run |

| 1pm | 2/6 | 15.8 | 36.8 | 55.5 | 33.4 | ||

| 9 am | 2/7 | 14.8 | 35.7 | 57.0 | 33.2 | 23 25 | |

| 10 am | 2/7 | 20 | 15.1 | 35.9 | 56.4 | 33.2 | 28 / 31 run |

| 4 pm | 2/7 | 40 | 17.6 | 38.3 | 54.3 | 32.9 | |

| 10 am | 2/8 | 45 | 21.2 | 39.0 | 54.6 | 33.2 | 40.2 24/26 |

| 1 pm | 2/9 | 19.8 | 38.8 | 55.5 | 32.9 | 23 26 | |

| seminar | |||||||

| 9 am | 2/13 | 15.8 | 36.8 | 57.7 | 32.7 | 22 26 | |

| 10 am | 2/14 | 15.1 | 35.7 | 57.5 | 32.3 | 40.2 29/31run | |

| 2pm | 2/15 | 30 | 17.6 | 38.1 | 54.6 | 32.3 | 22 26 |

| 8 am | 2/16 | 18 | 14.2 | 34.8 | 58.4 | 32.3 | 40.2 29/31run |

| 7 pm | 2/16 | 25 | 17.6 | 38.1 | 56.3 | 32.1 | 22 26 |

| 10 pm | 2/18 | 25 | 16.4 | 38.1 | 54.4 | 32.1 | 28/31run |

| Switch | the | thermo | from | basement | to *** | Blackline at | -24" |

| 3 pm | 2/19 | 35 | 19.4 | 39.3 | 34.5 *** | 32.0 | 40.6 22 26 |

| 11 am | 2/22 | 25.0 | 16.1 | 37.7 | 33.4 | 32.0 | 22 25 |

| 7 am | 2/25 | 20 | 14.2 | 34.8 | 33.6 | 32.0 | 40.6 21 24 |

| 10 am | 2/25 | 27 | 15.8 | 36.6 | 33.4 | 32.1 | 40.8 21 24 |

| Note : | top | house | 1500sf floor | used only | 65 gal oil | for 3 weeks | in cold Feb! |

| 6am | 3/3 | 6 | 7.6 | 32.9 | 34.8 | 32.1 | 41.7 run 24/30 |

| noon |

3/3 |

14.8 | 37.0 | 34.8 | 32.0 | 21/22 | |

| 2 am | 3/4 | 14.0 | 33.6 | 34.5 | 32.0 | ||

| 4 pm | 3/7 | 45 | 21.2 | 40.2 | 33.9 | 32.0 | 21/24 |

| 10 am | 3/8 | 48 | 21.2 | 41.1 | 34.3 | 32.0 | 41.5 |

| 9 am | 3/9 | 40 | 21.2 | 41.5 | 35.9 | 32.1 | 42.0 21/25 |

| 8pm | 3/9 | 32 | 20.3 | 40.8 | 36.3 | 32.1 | |

| 9am | 3/12 | 24 | 16.4 | 38.3 | 37.2 | 33.2 | 21/24 |

| 8am | 3/17 | 25 | 17.6 | 38.8 | 38.3 | 33.4 | 21/23 |

| 3pm | 3/17 | 50 | 21.2 | 42.0 | 38.6 | 33.2 | 45.1 |

| 8am | 3/23 | 25 | 17.6 | 38.6 | 38.6 | 34.5 | run 23/30 |

| 8:30am | 3/31 | 35 | 19.8 | 42.6 | 39.9 | 35.9 | 51.2 20/22 |

| 3pm | 4/36 | 50 | 24.8 | 46.0 | 41.1 | 36.3 | |

| 10am | 4/6 | 38 | 19.6 | 42.9 | 42.0 | 37.0 | 20/22 |

| 3pm | 4/10? | 19.4 | 43.3 | 41.1 | 36.9 | run 25/30 | |

| 10am | 4/14 | 21.2 | 44.2 | 39.9 | 36.6 | 52.1 20/22 | |

| Fuel from | Feb 1 | to 4/7 | 3/8 tank | = 248gal | = 26/week | for | 1500sf |

Another good web site for monitoring temperatures is:

Note that modern GSHP systems have Pressure Temperature Ports (P/T ports) for easy readings.

"Pete's Ports" available for purchase here:

Here is my model data.

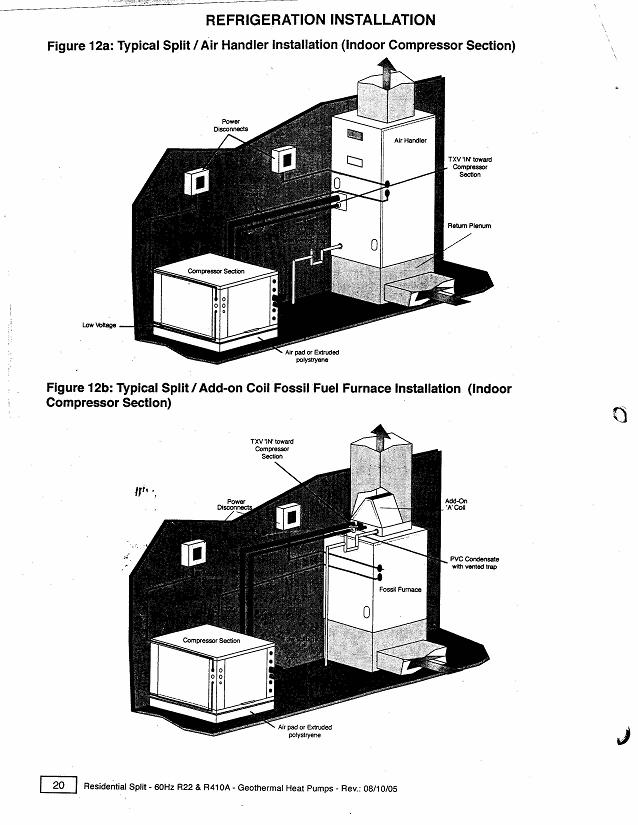

Unit came with a Warranty and Preventative Maintenance sheet. Here's a nice illustration from that document:

The Freon insides of the heat pump with access panel removed. (No Freon outside the house.)

The black insulated line runs to the air handler duct system.

The black insulated line has two copper pipes in it that contain Freon from the Heat Pump located 20' away in the same basement.

The inlet Freon is cool (40 degrees?) and the air handler fan pushes air across the coils inside the unit to the duct work for the house.

The outlet line returns the slightly warmer Freon back to the heat pump for new cooling, during this efficient air conditioning operation.

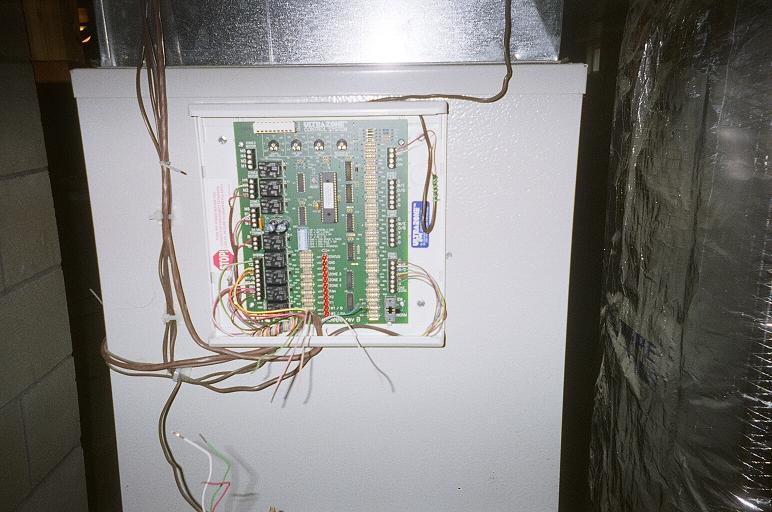

On the back side of the same first floor air handler, a circuit board is attached.

This allows the oil to kick in if ever needed, and regulates both upstairs zones in the main living area and in Mary's study.

Anyone wishing to contact Carl LePere at Air Professional Associates, LLC can email him at airprofs@aol.com

He is a licensed Connecticut Heating and Air Conditioning Contractor.

Thanks to Litchfield Building Inspector John Worthington for inspecting the heat pump !

There are few restrictive government regulations for the loop outside, but inside HVAC work requires a building permit.

Click Back to Index Page.